How Geotextile Manufacturers in India Maintain Quality Standards

Have you ever thought about what helps in regulating the drainage, filtration, reinforcement and overall protection of the urban landscape? Geotextiles are undoubtedly the unsung heroes that are buried deep beneath the critical railway lines, towering highways and monumental infrastructure in India. Geotextiles, in reality, are the woven, nonwoven and knitted fabric materials, widely used in various sectors such as railways, landfills, erosion and control. Considering their crucial role, it becomes an absolute necessity to maintain the quality standards while manufacturing geotextiles. Geotextile manufacturers in India these days are stressing upon the blend of regulatory compliance, advanced process of manufacturing, continual testing and customer-centric innovation. Here in this blog of Supreme Geotech, one of the most trusted geotextile fabric suppliers in India, we will shed light on the process which helps manufacturers maintain the top-notch quality of geotextile in the marketplace.

The Factors That Geotextile Manufacturers Follow For Maintaining Quality

As geotextiles are wisely used in every sphere, ranging from industrial projects to infrastructure and others. To keep pace with this growing demand, geotextile manufacturers in India are stressing different factors that we are going to highlight below. Let’s delve into the pointers below to find out.

Commitment to quality-

The leading manufacturers in India stress quality right from the stage of sourcing, and they rely entirely on the procurement of top-notch quality materials such as 100% virgin resins like PP and PET to comply with the global standards. This commitment ultimately aids in woven and non-woven geotextile manufacturing.

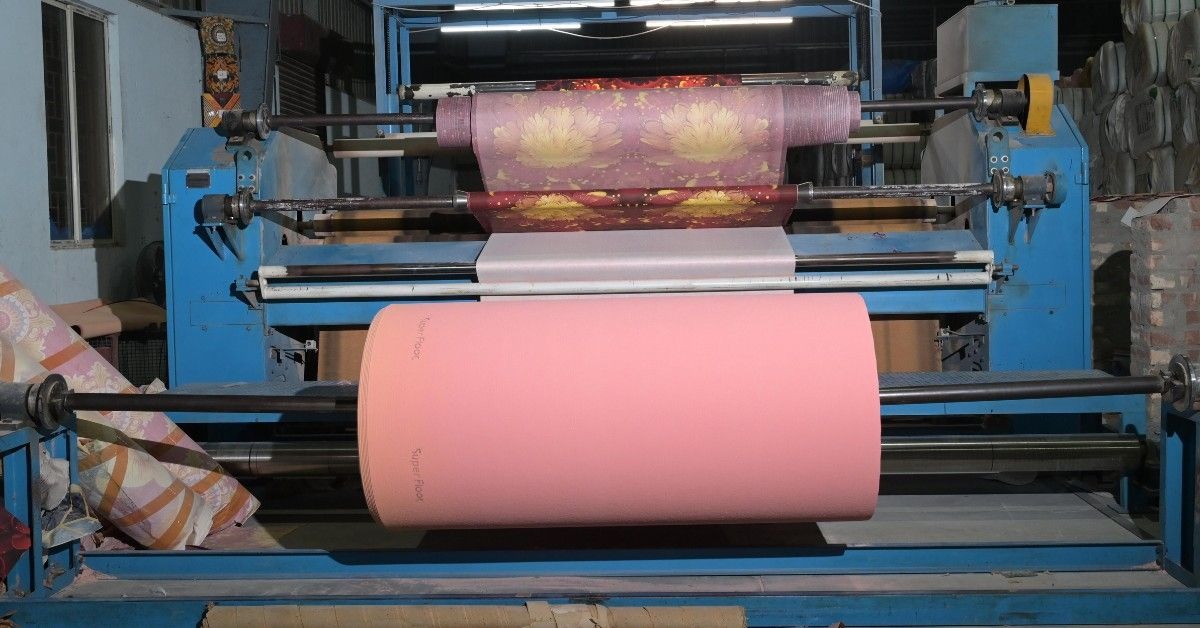

State-of-the-art production facilities-

The modern Indian geotextile plants are equipped with advanced extrusion lines, needle-punching machines, weaving looms and lamination units. It, in turn, allows the manufacturers to create a wide variety of woven and non-woven geotextile fabrics. The cutting-edge technological advancement in the production facilities is conducive to minimising human errors and preserving product uniformity.

Adherence to regulatory standards-

Top quality in geotextile manufacturing is now legally mandatory. To keep pace with the market standard, the Bureau of Indian Standards has issued Quality Control Orders, which necessitate all geotextiles to comply with the BIS certification standards. Only the products that can successfully qualify the rigorous checks are allowed to bear the ISI mark. For the geotextile manufacturers out there in India, adherence to such protocols offers a competitive advantage to reign in the marketplace and to create reliability in the minds of the business owners who are buying these fabrics for commercial usage.

Advanced testing and research-

The eminent geotextile manufacturers in India invest heavily in well-equipped laboratories where every batch of geotextile items undergoes comprehensive mechanical and durability tests to stand out. Such testing includes accelerated aging, UV resistance, strength testing, and permeability evaluations to simulate a range of real-world environmental conditions. This kind of strict testing and ongoing research practices guaranteeing high-qualityguarantees geotextile fabrics.

Customisation and client-centric approach-

The reputed geotextile manufacturers like Supreme Geotech recognise an inextricable association between durability and project-specific functionality. Working closely with the client base, we provide product customisation based on site-specific soil, load and environmental requirements for maximum utility and minimise the extra cost of maintenance.

Continual improvement-

Unlike the manufacturers of other countries, in India, the leading Indian manufacturers are dedicated to operating under a quality management system to inculcate a culture of improvement and innovation. At Supreme Geotech, we are presently concentrating on designing training sessions for the workers, which take into account everything from SOP to regular review, technology upgrades to help the factories in delivering the best performance.

Final Thoughts

The maintenance of high-quality standards by geotextile manufacturers in India is a critical factor in the nation’s infrastructure success story. In 2025, when the entire world is concentrating on the top quality of the outputs, rigorous quality standards are not at all an optional business practice, but they stand for a multifaceted commitment. Ultimately, this stringent approach plays a vital role in ensuring the best quality of the geotextile fabrics that contribute to the sound performance of the businesses. To know more about the quality control practices, continue reading the blogs of Supreme Geotech, one of the reputable Geosynthetics manufacturers in India.

FAQs:

Why is BIS certification mandatory for geotextiles?

BIS certification is mandatory for manufacturers as it helps to ensure that the products meet safety, reliability and performance specifications. The critical projects associated with civil engineering and infrastructure projects must adhere strictly to the BIS certification to produce the best outputs.

How do manufacturers ensure the materials are of high quality?

The leading manufacturers generally rely on 100% virgin polymers, melt flow index and UV stabilisers to ensure the topmost quality of the product items.

What is the "ISI Mark" and why is it important for buyers?

The ISI Mark is the standard certification mark issued by the BIS. For the buyers, this mark stands for an assurance that the product has successfully passed the strict quality management system.